Fiber optic cables carrying massive amounts of information on pulsating beams of light are a critical part of the physical infrastructure supporting our digital society. By their nature, these cables are highly exposed, spanning huge distances in territories beyond the control of a network operator whether underground, under water or on aerial cables, and popping up in equipment huts. While it may seem counterintuitive, studies have shown that underground fiber is the most susceptible to harm, with the most frequent mode of failure being dig-ups. Other popular failure causes include rodents, firearms, and floods. Fiber is also subject to degradations in performance, usually occurring at splice points, where fibers join with each other, and at equipment connections.

The modus operandi for maintaining fiber optic cable has been to wait until a hard failure occurs – bringing down all the services the fibers are carrying – and then scrambling work crews madly. They typically follow three steps: determining where the failure occurred, instituting a temporary fix to restore services, and finally effecting a permanent repair to the fiber.

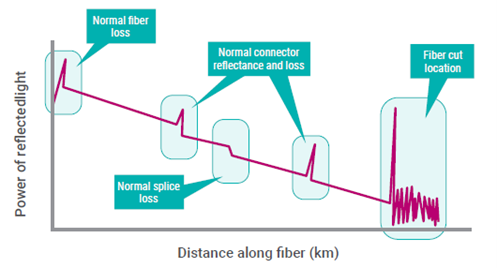

In the first step, a crew is usually dispatched to the suspected general area of the failure with a handheld OTDR (Optical Time Domain Reflectometry) device, which is essentially a fiber optic radar. Once the crew finds a convenient location to tap into the failed cable, like in an equipment hut, the OTDR device shoots a beam of light into a fiber. When the beam hits a discontinuity in the fiber it reflects back some of the light, creating a physical profile of the fiber, showing splice points, and hard breaks causing failures.

This information then guides the dispatch of another work crew to the more precise location of the break, to find it definitively and fix it. Multiple truck rolls are required, and on average, it takes about 14 hours to effect a permanent repair.

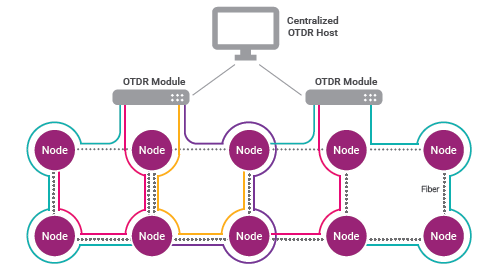

Advances in compact OTDR technology are now enabling fiber health management to step out of the Stone Age. By strategically distributing OTDR modules throughput the fiber plant it becomes possible to continuously monitor fiber health from the comfort of a centralized control center. This approach has two big advantages. When a hard failure occurs, the location process can begin immediately, eliminating the need to dispatch a crew with a handheld OTDR. In addition, by creating regular profiles of a fiber over time it is possible to detect and address degradations before they become service affecting.

A fully-featured centralized OTDR system includes the following capabilities:

- Ability to work on any physical fiber optic network, supporting any vendor’s IP or optical networking gear.

- Working in an “in-service” mode, meaning using wavelengths of light to monitor the fiber that do not interfere with wavelengths carrying services.

- Ability to monitor the entire physical plant by supporting multiple ports on each OTDR module.

- Locating faults with pinpoint accuracy, to within a few meters of a break, even over many tens of kilometers of fiber.

- Linking to a Geographic Information System (GIS) to translate distance down a fiber to geographical X and Y coordinates to guide a repair crew.

- Trend analysis to compare snapshots of a fiber’s characteristics over time to identify problems before they become service affecting.

Learn more about how Ribbon delivers fiber health management using centralized OTDR.